Effective power system planning isn’t just about planning for the worst scenarios, but is also about economics. Production cost modeling provides a critical tool, allowing planners to simulate power system market operations and quantify the financial impacts of different scenarios. This post will describe the vital role of this tool in shaping cost-conscious transmission infrastructure.

Background

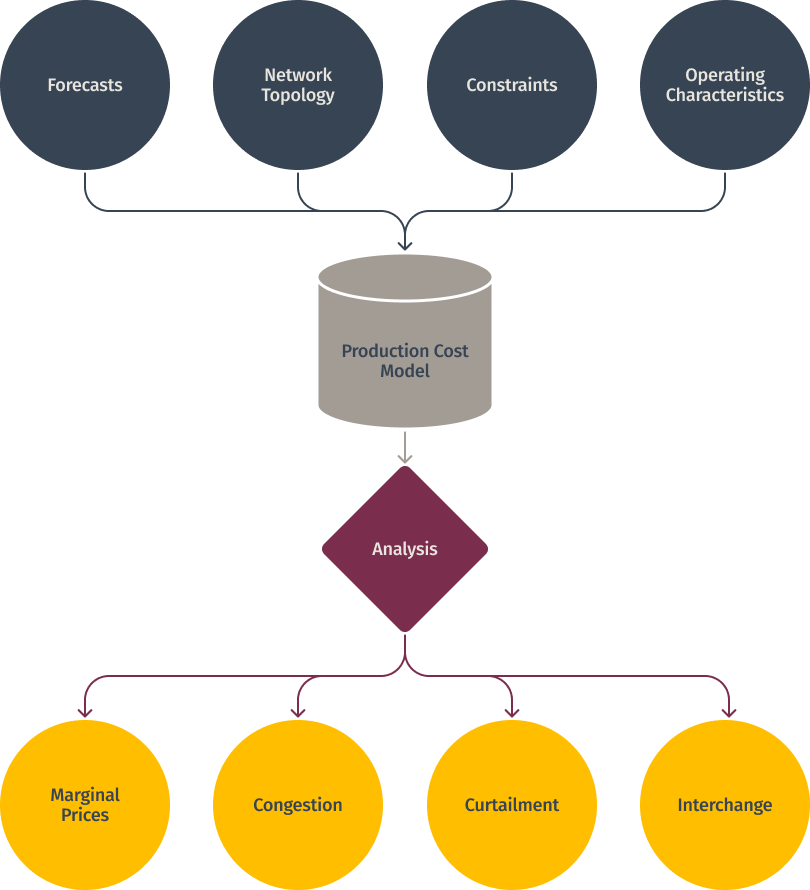

At a high level, production cost analysis involves simulating the operation of a power system over a period of time, typically a year, to determine the total costs of electricity production. By modeling the dispatch of generators to meet load at the lowest possible cost while respecting system limitations, this analysis provides crucial insights into the total cost of electricity production for a wide range of use cases, which can include evaluation of generation portfolios, transmission planning, evaluation of congestion and curtailment risk, revenue forecasting, and emissions analysis.

Modeling

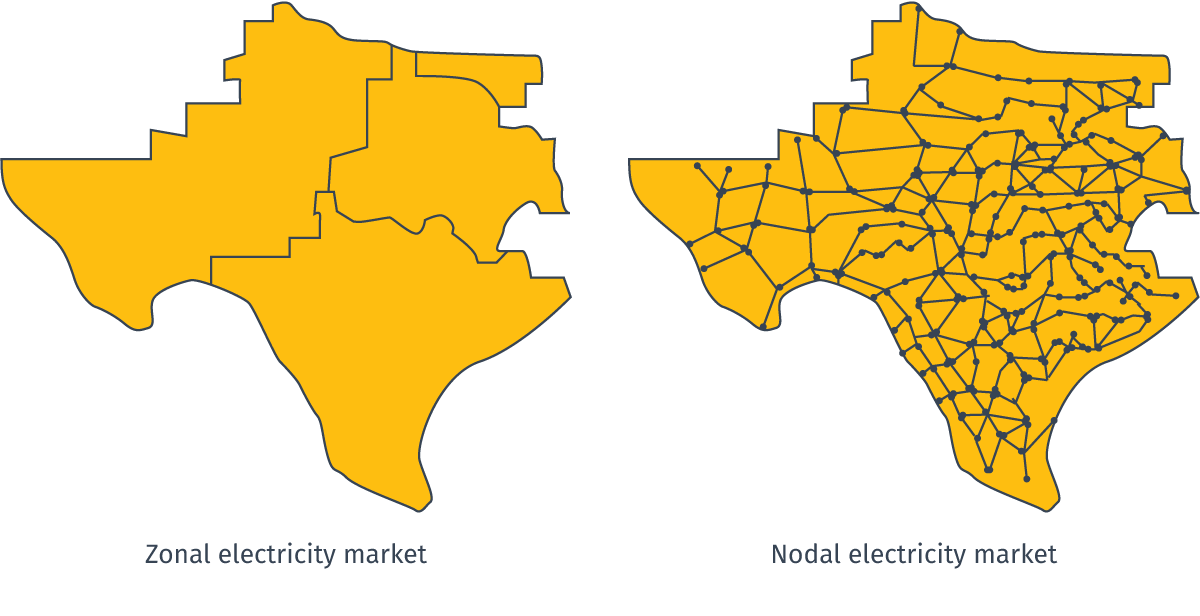

As with other types of power system analysis, production cost analysis starts with modeling. A production cost model begins with a representation of network topology, whether using a simplified “pipe and bubble” zonal topology, or using detailed nodal topology imported from a power flow model.

From here, transmission constraints are defined, either as paths between zones in a zonal analysis, or as specific transmission elements in a nodal analysis. These transmission constraints are respected when committing and dispatching generators during simulation. As these are critical assumptions to make, a constraint analysis is usually warranted to choose the constraints with the most impact while minimizing the number of constraints to reduce market simulation runtime.

Generators with no fuel cost (e.g. wind, solar, hydro) are assigned time-series forecasts based on projected natural resource output for the location, usually based on historical trends. Conventional generators are also modeled with various operating characteristics such as ramp time, fuel consumption, and effluent production. Similarly, forecasted time-series profiles are assigned to loads, usually assigned on a zonal basis and allocated based on typical load weighting taking into account non-conforming loads.

While one model is often enough to make certain determinations, it is often useful to have another model to compare results against. For example, an engineer may want to evaluate the congestion reduction provided by a transmission upgrade. In this situation, the engineer would likely want to develop a base model without the upgrade and a study model with the upgrade to compare the analysis results.

Analysis

Once models are developed, market simulation may be performed. This simulation, mimicking an organized energy market, performs a Security Constrained Unit Commitment (SCUC) algorithm to optimize the generators committed at the beginning of each week for minimum cost subject to the user’s defined constraints while also considering generator operating characteristics, such as ramp time and outage schedules. The simulation then performs a Security Constrained Economic Dispatch (SCED) for each interval in the week to determine the specific generator dispatch to minimize cost subject to constraints while meeting load for the region.

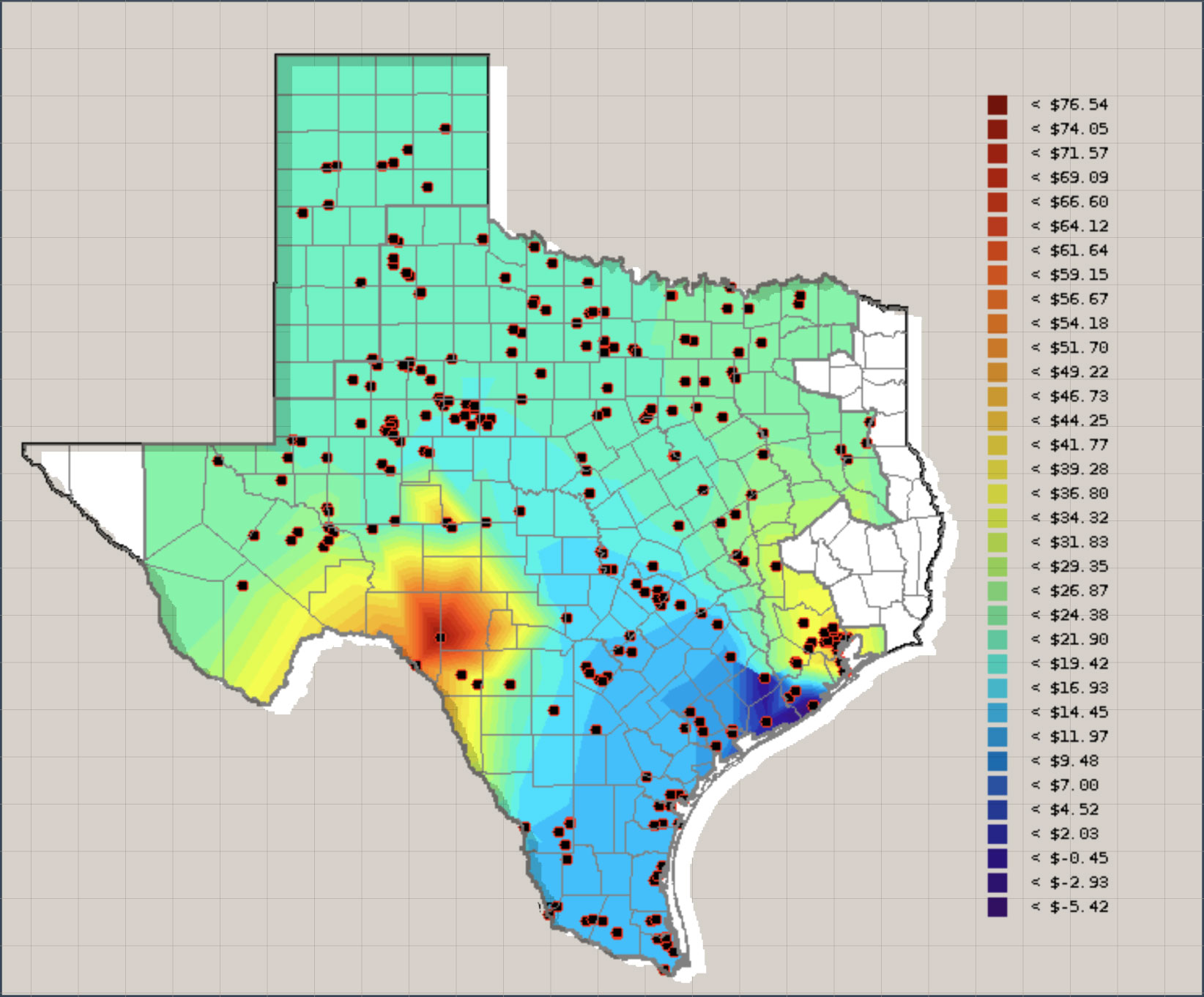

Market simulation primarily results in an optimized solution for each time interval, from which several other metrics are determined. Locational Marginal Prices (LMPs) are determined at each bus (or zone, in the case of a zonal simulation) which reflect the marginal price of energy purchased or sold at the location. These are also affected by congestion, which leads to separation of marginal prices on either side of a transmission constraint. Curtailment amounts for renewable resources are also determined. Congestion costs may be summed per constraint to determine the potential savings by relieving the constraint, for example with an upgrade. From the resulting generation dispatch and load for the time interval, zonal or regional interchange may be calculated. Production costs are calculated from the dispatched generation’s fuel consumption, along with effluent amounts such as carbon dioxide or nitrogen oxide emissions.

Benchmarking the simulated results against real-world operational data is important for validating the model’s performance, and ensures that the model realistically represents the real-world power system’s behavior. This can be performed by comparing key metrics from the simulation, such as LMPs, generator dispatch, and congestion patterns, with historical operational data from the market being simulated. Significant discrepancies between simulated and actual data may indicate the need to refine model assumptions, parameters, or constraints. By adjusting the model to better align with real-world observations, the accuracy and predictive capabilities of the production cost analysis are improved.

Additional simulations can be performed on different time horizons (e.g. 5 years and 10 years in the future) to extrapolate potential benefits for the life of a project. Sensitivity analysis can also be performed to explore the effects of various fundamental assumptions like fuel or load forecasts, which may give further confidence around a decision such as selecting a transmission upgrade that provides benefits across a wide range of operating conditions.

Production cost analysis plays a critical role in determining the viability of proposed generation interconnection projects. By simulating the integration of a new generator into the existing power system, analysts can assess its impact on LMPs, congestion costs, and overall system production costs. This analysis helps determine if the proposed generator can be economically dispatched and its investment recouped. Further, it can reveal potential transmission upgrades needed to accommodate the new generation and who should bear those costs. Through various scenarios, economic analysis can evaluate the project’s financial robustness under varying fuel prices, load forecasts, and renewable resource availability, ultimately informing investment decisions and ensuring the project’s long-term economic viability.

As the energy industry undergoes transformation with the rise of renewables and evolving demand patterns, the role of production cost analysis in transmission planning becomes even more critical. Its ability to model complex interactions and quantify economic impacts under various future scenarios makes it an invaluable tool for navigating this uncertainty. By understanding the cost implications of different transmission choices, we can proactively build the infrastructure needed to support a cleaner, more reliable, and affordable energy system.

Loved the article? Hated it? Didn’t even read it?

We’d love to hear from you.