“The creation of a thousand forests is in one acorn.”

—Ralph Waldo Emerson

Welcome back to the control room! In Part 1, you learned the vocabulary of the power grid, including the fundamentals of power, frequency, and voltage. You have your operator’s toolkit. Now, it’s time to meet your team. Today, we’re going to the source. We’re going to look at the machines that actually create the electricity you’re responsible for.

We’ll examine the generation side of the power grid by reviewing some of the largest and most powerful machines on the planet, from city-sized hydroelectric dams to sprawling fields of solar panels. By the end of this session, you’ll understand the fundamental difference between how a 1-gigawatt nuclear reactor and a 10-kilowatt rooftop solar installation make power, and you’ll see how you have to manage them all to keep the lights on.

From Distributed to Centralized Power

Look at the main map on your screen. You see those large circles? Those are your big power plants, sending electricity hundreds of miles away. You take that for granted now, but it wasn’t always this way. When Thomas Edison opened the first commercial power plant, the Pearl Street Station in Manhattan in 1882, he was pioneering a model of distributed generation (although they didn’t call it that!). Power was made right where it was used. The problem was, Edison’s system used Direct Current (DC), which was incredibly inefficient to transmit. It couldn’t travel much more than a mile. To power a city, you would have needed a small power plant in every single neighborhood.

The development of Alternating Current (AC) and the transformer changed everything. Suddenly, you could generate massive amounts of power at a single, highly efficient centralized station, “step up” the voltage for long-distance transmission (we’ll talk about this in the next post in the series), and then “step it down” for safe use. That became the blueprint for the grid you see before you. For almost a century, the idea of a customer generating their own electricity was a historical curiosity. It’s only recently, with the rise of rooftop solar, that we’ve seen anything close to a return to the distributed model Edison first envisioned.

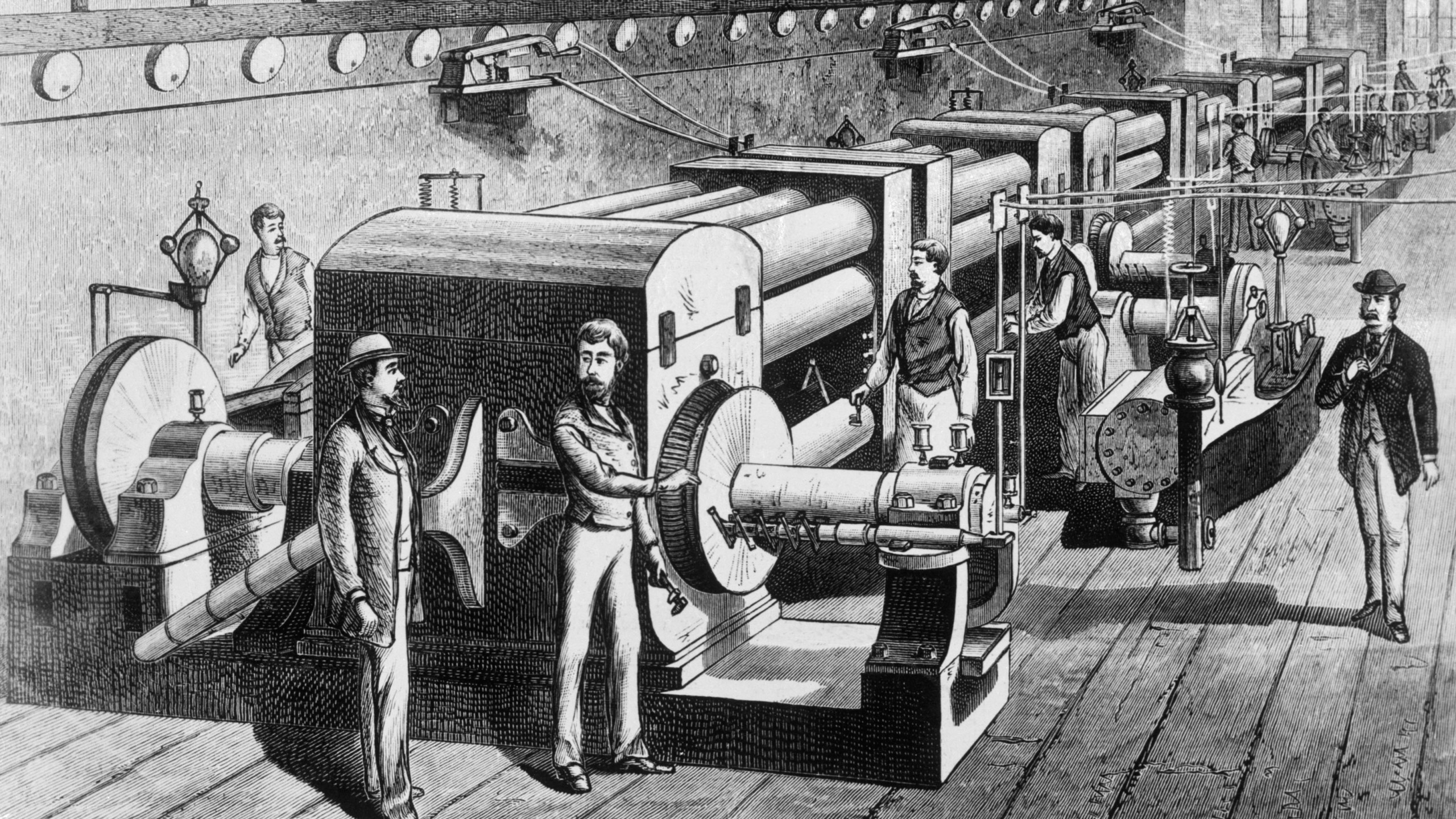

The Synchronous Generator, The Heart of Your System

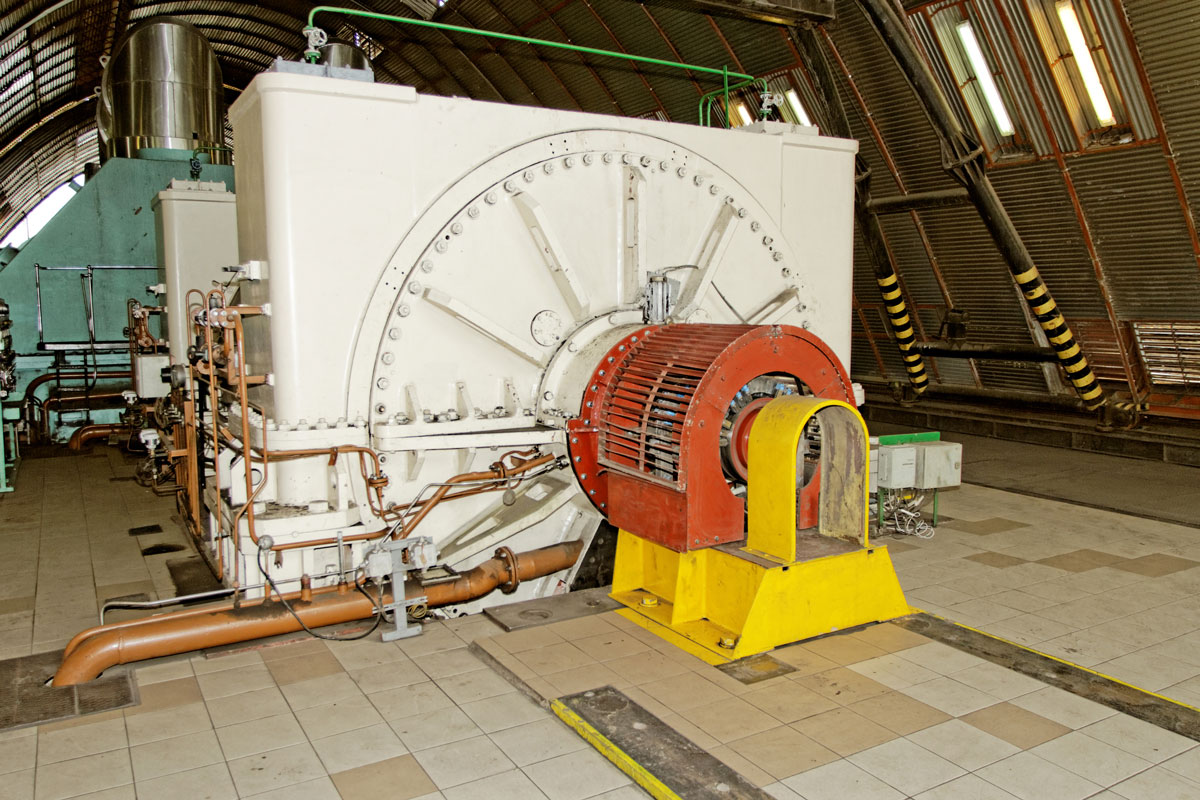

At the center of nearly every one of those large power plants sits one essential machine, the synchronous generator. This is the machine that does the real work. It takes mechanical rotation from steam, gas, or water and transforms it into the alternating current you manage.

The principle it uses is called electromagnetic induction. Now, before we move on, you need to internalize this concept. Discovered by Michael Faraday in 1831, it’s a fundamental law of physics. It states that a changing magnetic field will “induce” an electric current in a nearby wire. In a generator, you achieve this by spinning a powerful magnet (the rotor) inside a stationary coil of wires (the stator). This fundamental link between magnetism and electricity is the foundation of your entire system. Without it, the grid wouldn’t work.

Operator Briefing: The History of the Generator

While Faraday discovered the principle, it was innovators like Nikola Tesla and George Westinghouse who perfected the AC synchronous generator. A key advantage of AC generators was their simplicity. DC generators needed a complex, failure-prone part called a commutator to mechanically flip the current’s direction. AC generators didn’t need this, making them more robust and easier to scale to massive sizes. This mechanical superiority was another decisive factor in AC winning the “War of the Currents” and becoming the global standard for the grid you’re managing today.

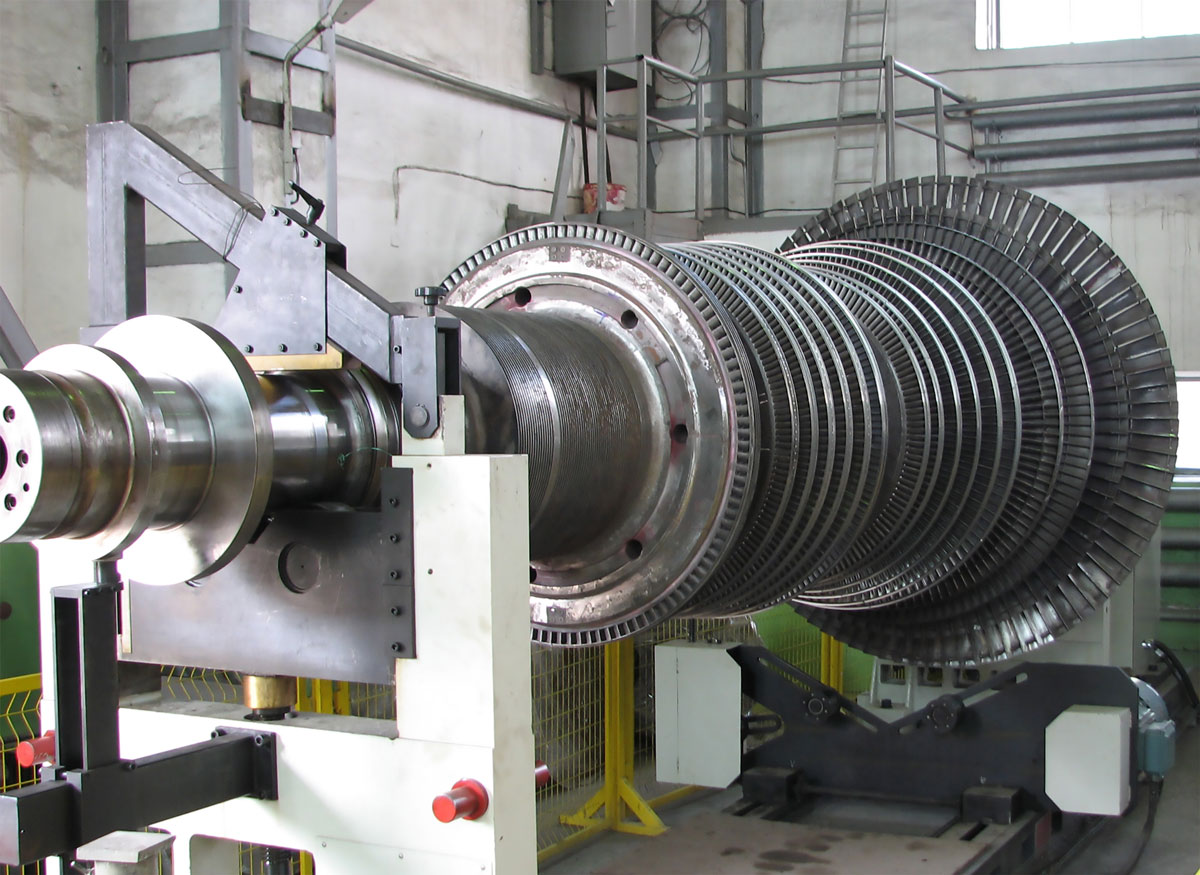

Of course, generators don’t just spin on their own. They need to be driven by a prime mover, the machine that converts a primary energy source into rotation. A turbine is the most common type. Think of it as the engine connected to the generator’s driveshaft. The type of turbine used depends on the fuel source, for example a steam turbine for coal and nuclear plants, a gas turbine for natural gas, and a water turbine for hydroelectric dams.

Anatomy and Operation of the Generator

As I mentioned, a generator has two main parts, the rotor (the spinning electromagnet) and the stator (the stationary part holding the coils of wire). As the turbine spins the rotor, its magnetic field sweeps past the stator windings, inducing an AC voltage.

The speed of that rotation isn’t arbitrary, it’s precisely synchronized with the grid’s frequency. For a typical 2-pole generator on your 60 Hz system, that’s exactly 3,600 RPM. This physical movement of the poles of the rotor past the stator is what creates the 60-cycle-per-second sine wave you learned about in Part 1. It is the source of your grid’s heartbeat. The more magnetic poles a generator has, the slower it needs to spin to produce that same 60 Hz frequency.

The generators that power your grid are massive, some weighing hundreds of tons. This immense physical mass provides one of the most critical services for grid stability, inertia. This is simply a physical resistance to changes in speed. Think of it like a massive, heavy flywheel. Once it’s spinning at 3,600 RPM, it has enormous momentum and doesn’t want to slow down. This acts as a buffer for your entire grid. If a large power plant suddenly trips offline, the inertia from all the other spinning generators across the continent keeps the frequency from crashing instantly, giving you precious seconds to respond. As we’ll discuss later, the fact that modern renewables don’t have this physical inertia is one of the biggest challenges you’ll face. This massive, spinning machine isn’t just a passive source of power; its physical properties give you direct control over the grid’s most critical vital signs.

Your Levers of Control for the Grid’s Vitals

As you learned in Part 1, your primary job is to manage two critical quantities, frequency and voltage. The synchronous generators in your fleet give you two distinct levers to control these vitals.

Your first lever controls frequency by managing real power. Your grid’s frequency is a direct reflection of the real-time balance between supply and demand. To keep it at a steady 60 Hz, you’ll dispatch orders to control the generators’ real power (MW) output. By telling a prime mover to push more or less steam or water through its turbine, you increase or decrease its output to perfectly match what your customers are using.

Your second lever controls voltage by managing reactive power. To manage the grid’s voltage, you’ll order generators to adjust their reactive power (MVAR) output. They do this by changing the strength of the rotor’s internal magnetic field with a device called an exciter. This is the “foam in the beer” we talked about in part 1. Injecting it into the grid props up voltage, while absorbing it brings voltage down.

Ancillary Services, The Grid’s Support System

The functions you control, frequency and voltage support, are part of a broader category of essential grid functions called ancillary services. These are all the jobs generators must do besides just producing raw energy to keep your grid stable. These services include:

- Frequency Regulation: This is the continuous, second-by-second balancing act you perform by managing the real power output of your generators to keep the grid’s heartbeat at a steady 60 Hz.

- Voltage Control: This is your tool for managing grid pressure. By ordering generators to produce or absorb reactive power, you keep the voltage within safe operating limits across the entire system.

- Operating Reserves: This is your contingency plan. You’ll keep some power plants either spinning but unloaded (spinning reserve) or ready to start up in minutes (non-spinning reserve). This ensures that if a large power plant fails, you have backup power ready to deploy instantly.

- Black Start Capability: This is needed in the event of a total grid collapse, since most power plants need electricity from the grid to restart. It’s one of the great ironies of your job; a machine designed to create electricity on a massive scale depends on a small amount of it to get started. A few specialized black start units can start up on their own using on-site diesel generators. They are the first spark you’ll use to re-energize the grid, which can be a lengthy and time consuming process, since load and generation need to stay carefully balanced.

But not every generator on your map can provide these critical services equally. To understand who to call on and when, you need to divide your fleet into two fundamental teams, those you can command at will, and those that are dependent on external factors like the weather.

Your Team of Dispatchable vs. Non-Dispatchable Generation

- Dispatchable Generation refers to the resources in your fleet that you can control on command. You can turn them on, turn them off, or ramp their output up and down. Conventional thermal plants (coal, gas, and nuclear) and hydroelectric dams with large reservoirs are the classic examples of dispatchable resources. However, it’s important to remember that ‘dispatchable’ doesn’t always mean ‘fast.’ While a gas plant can ramp up in minutes, a large nuclear plant is designed for steady, continuous operation and can’t be spun up or down quickly.

- Non-Dispatchable Generation, often called variable generation, refers to sources whose output depends on external factors like the weather. You can’t order the wind to blow or the sun to shine. This means their output is dictated by nature, not by your commands. This introduces a new layer of uncertainty into your operations. While you know exactly how much fuel a coal plant has, you have to rely on sophisticated weather forecasting to predict how much wind and solar power will be available hours or even days in advance. This fundamental variability is a central challenge you’ll have to manage every minute of every day.

This distinction is crucial, as it determines the specific roles different plants play in your daily game plan.

The Daily Game Plan for Baseload, Peaking, and Load-Following

Just because a plant is dispatchable doesn’t mean you use it in the same way as another. You’ll manage your dispatchable fleet in three main roles to match the daily rhythm of electricity demand.

- Baseload Plants meet the constant, minimum level of electricity demand that your grid experiences 24/7. Nuclear and large coal plants are the classic examples. They are very efficient when running at full tilt, but they are slow and expensive to start up and shut down.

- Peaking Plants (or “peakers”) provide the extra electricity needed during the “peak” hours of the day, like on a hot summer afternoon. These are typically natural gas turbines that can start up in minutes. They are less efficient and more expensive to run, but their flexibility is essential.

- Load-Following Plants adjust their output throughout the day to “follow” the rise and fall of demand between the baseload and peak levels. These plants are often efficient combined-cycle natural gas units.

This complex coordination is performed by a diverse cast of technologies. Now, let’s look at the actual machines that fill these roles.

Thermal Generation

For over a century, the foundation of your fleet has been heat. The basic idea is to use a heat source to boil water, create high-pressure steam, and use that steam to spin a turbine. This process follows the Rankine cycle. The main difference between these plants is the fuel they use.

- Conventional Steam was the workhorse for much of the 20th century. These plants burn a fuel, usually pulverized coal or oil, in a massive boiler to create high-pressure, superheated steam, which then spins a turbine.

- Combined-Cycle is a more modern and efficient approach, used with natural gas. This is like a jet engine bolted onto a steam plant. A gas turbine spins a generator directly, and then its hot exhaust is used to boil water and drive a second steam turbine, effectively reusing the excess heat that would have otherwise been wasted.

- In nuclear power plants, people often imagine a complex and mysterious process. And while the safety and monitoring systems are extraordinarily complex, the principle is simple. A nuclear reactor is just a very sophisticated way to boil water. The heat from a controlled nuclear fission reaction creates the steam needed to spin a turbine.

- You also have other thermal sources in your fleet. Geothermal plants tap directly into the Earth’s heat. Biomass plants burn organic materials. Waste-to-energy facilities use the heat from incinerating trash.

In all these cases, the fundamental story is the same. Heat creates steam, and steam spins a turbine. It’s a powerful reminder that much of your grid still relies on a principle that is centuries old. This reliance on heat, however, stands in stark contrast to another ancient power source.

Hydroelectric Power

Long before electricity, water was one of humanity’s oldest power sources. Hydroelectric generation applies this ancient principle on a massive scale. It takes the potential energy of elevated water and converts it into electricity with almost no fuel. The first major U.S. hydro plant at Niagara Falls in 1895 proved this could power entire cities, paving the way for the massive dams of the 20th century. This principle is taken to its extreme at facilities like China’s Three Gorges Dam, the single largest power station of any kind on the planet.

Hydroelectric plants come in a few main varieties:

- An impoundment dam is a large dam that holds back water in a reservoir. The height difference, called the head, creates pressure that spins turbines.

- Run-of-river systems use the natural flow and drop of a river. They are less flexible but also less disruptive to ecosystems.

- Pumped storage is your grid-scale battery. When electricity is cheap, the plant pumps water uphill. When demand spikes, the water is released downhill through turbines.

Renewable Generation

Thermal and hydro plants are dispatchable resources that rely on spinning machines. But your newer generators, like wind and solar, are non-dispatchable and rely on natural flows. They also connect to the grid differently, by using power electronics.

Operator Briefing on Capacity Factor

This variability highlights an important concept called the capacity factor. This is a measure of how much a plant actually produces over a year compared to its maximum possible output. A nuclear plant might have a capacity factor over 90%. A solar farm, which only generates power during the day, might have a capacity factor of 20-30%. This doesn’t mean solar is worse, it just means when you hear “2 GW of solar capacity”, there is a lot less actual energy that will be generated than if you had a 2GW nuclear plant. Because of this, its role in your fleet is fundamentally different.

The phrase “power electronics” means using solid-state electronics to convert and control electric power. Think of it as a sophisticated adapter. Solar panels produce DC power, and wind turbines produce AC at a variable frequency. Neither is compatible with your grid’s rigid 60 Hz standard. Power electronics, typically in a device called an inverter, act as the translator. They take the variable power and reassemble it into a perfect 60 Hz sine wave. This is why you’ll often hear wind and solar referred to as Inverter Based Resources (IBRs).

There are many types of generation from natural flows, but the two you’ll deal with most are wind and solar.

- Wind power comes from turbines that convert the kinetic energy of air into rotation. The blades spin a shaft connected to a gearbox, which increases the speed for the generator. Because wind speed changes, the power produced is variable and must be converted by power electronics.

- Solar power’s most common form is Photovoltaic (PV), which uses semiconductor cells to directly convert sunlight into DC electricity. An inverter then converts this to grid-compatible AC. A less common method is Concentrated Solar Power (CSP), which is becoming less prevalent as the cost of PV panels continues to fall.

The Challenge of Oversupply, Curtailment and the Duck Curve

The variability of wind and solar creates another major challenge for you. What happens when it’s a very sunny and windy day, but electricity demand is low? Your grid can become overwhelmed. When this happens, you will be forced to curtail renewable generation, ordering wind and solar farms to reduce their output and essentially wasting clean energy.

This problem is perfectly illustrated by the duck curve. This chart shows the net load your traditional power plants must serve. In the middle of the day, when solar is at its peak, the demand on your traditional plants plummets, creating the “belly” of the duck. But as the sun sets, solar generation disappears, and people come home from work. This creates an incredibly steep ramp-up in demand that you must meet in just a few hours, forming the duck’s “neck.” This steep ramp is a huge operational challenge, and it’s one of the clearest signs on your screen that the very nature of your fleet is changing.

The Transition to a Hybrid Grid

For most of the grid’s history, your fleet was dominated by giant spinning machines. But now, you’re managing more inverter-based resources. This shift from physics to software presents new, complex challenges.

The most significant is the loss of physical inertia. Without the stabilizing momentum of spinning steel, your grid loses its buffer. Standard inverters are grid-following, they simply sense your grid’s frequency and follow along. They don’t actively stabilize it.

This leads to a second problem called ride-through. During a grid fault, many older inverters are programmed to disconnect to protect themselves. This can create a dangerous cascade. As detailed in NERC and WECC reports on the 2021 Odessa Disturbance, a simple transmission fault caused over 1,100 MW of solar generation to trip offline almost instantly, putting the entire regional grid at risk. Because these inverters are driven by software, they can also introduce new instabilities. If thousands of inverters are configured with similar settings, they can interact in unexpected ways, creating unwanted oscillations.

The good news is that engineers are developing solutions. The next generation of inverters are grid-forming. They are programmed to actively create their own stable voltage and frequency, acting like digital versions of a synchronous generator. They can provide “synthetic inertia.” However, this technology is still evolving. Some experienced operators are skeptical, questioning whether a software algorithm can truly replace the physical properties of a massive spinning generator. Despite these concerns, grid-forming technology is likely the key to operating the grid of the future.

New Solutions and a Smarter Grid

All of these challenges are driving a wave of innovation across your fleet. Large-scale Battery Energy Storage Systems (BESS) are becoming a key tool for you to solve the duck curve problem. These utility-scale batteries can charge with cheap, abundant solar power during the day and then discharge that energy back onto the grid during the evening ramp. Because their inverters can respond in milliseconds, they can also provide extremely fast and precise ancillary services like frequency regulation, acting as a digital stand-in for some of a synchronous generator’s stabilizing functions.

You’re also seeing the rise of hybrid power plants, which combine different technologies at a single site to create more versatile and reliable resources. The most common is solar-plus-storage, where a solar farm is co-located with a large battery. This allows the plant to provide a more consistent output, offer valuable ancillary services, and save on land and interconnection costs. In fact, this model is becoming so important that some grid operators are now requiring new solar projects to be built with a battery attached, directly addressing the midday glut of solar and turning it into a dispatchable evening resource.

Finally, your grid itself is becoming more intelligent. Virtual Power Plants (VPPs) are cloud-based systems that aggregate thousands of small, distributed resources like rooftop solar, home batteries, smart thermostats, and even electric vehicle chargers. By controlling these resources in a coordinated way through sophisticated software, a VPP can act just like a traditional power plant under your command, providing you with another flexible tool to manage the grid.

But all these new technologies, from batteries to VPPs, don’t get built in a vacuum. They have to compete in the system that decides who generates power and when. To understand that, you need to understand a little bit about the economics of the grid.

The Role of Power Markets

So far, we’ve talked about the engineering and what types of generation are at our disposal. But what determines which plants you can actually call upon and when? In many parts of the country, the answer is economics. We’re just going to touch on this briefly, as it’s a deep topic we’ll explore in a future training session, but you need to understand the basics. These regions operate competitive power markets, which function much like a stock market for electricity.

This is a two-step process involving planning ahead and then acting in real-time. The first step is unit commitment. Because your large baseload plants can take hours to start up, you can’t just flip a switch. A day in advance, or in some areas longer timeframes, you’ll look at the forecast and “commit” certain plants, ordering them to be ready. This creates the pool of available generators.

The second step is economic dispatch. On the day of, plant owners submit bids to you, stating how much electricity they can produce and the minimum price they are willing to accept. You then stack these bids from cheapest to most expensive. To meet real-time demand, you “dispatch” the lowest-cost resources from the committed pool first, working your way up the stack until demand is met. This “merit order” dispatch has a profound impact on your generation mix. Renewables, with zero fuel cost and often subsidies, are almost always the cheapest. They are followed by efficient gas and nuclear plants. Older, less efficient coal and oil plants are the most expensive and are only called upon during high demand. This relentless economic pressure is a major driver of the energy transition.

Understanding this economic layer is just as important as understanding the engineering involved. The decisions made in these markets dictate not only how you operate the grid today, but also which types of power plants will be built to serve the grid of tomorrow. It’s the economic system that shapes your entire fleet.

Conclusion of the Session

So, that’s your fleet. We’ve journeyed from the spinning heart of the power plant, the synchronous generator, to the cutting edge of the modern grid. You’ve seen that generating electricity is about far more than just making power. It’s a complex interplay of physics, engineering, and economics, requiring you to constantly manage frequency, voltage, and a host of ancillary services.

For a century, the synchronous generator anchored your grid with its physical inertia. Now, a revolution is underway. The shift to a hybrid grid, rich with inverter-based resources, is replacing the simple laws of physics with the complex logic of software. This brings incredible opportunities, but also profound challenges, from the loss of inertia and the puzzle of the duck curve to the new economic realities of power markets. Your job is no longer just about managing massive machines, but also about the sophisticated controls and market forces that dictate their every move.

In the next training session, we’ll follow the electricity these machines create as it begins its journey outward, onto the high-voltage network of the transmission system.

Loved the article? Hated it? Didn’t even read it?

We’d love to hear from you.